Say Cheese!

New Mexico Farmsteads Craft Cheese ... Without Kraft

Stately cheeses

Courtesy of South Mountain Dairy

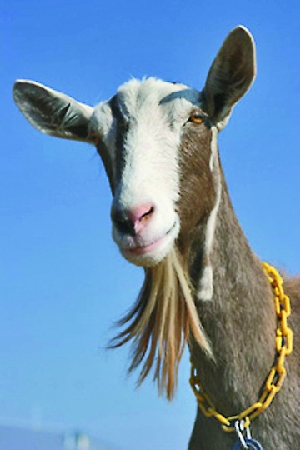

Lizette, one of “the girls” at South Mountain Dairy, produces milk for a variety of goat cheeses.

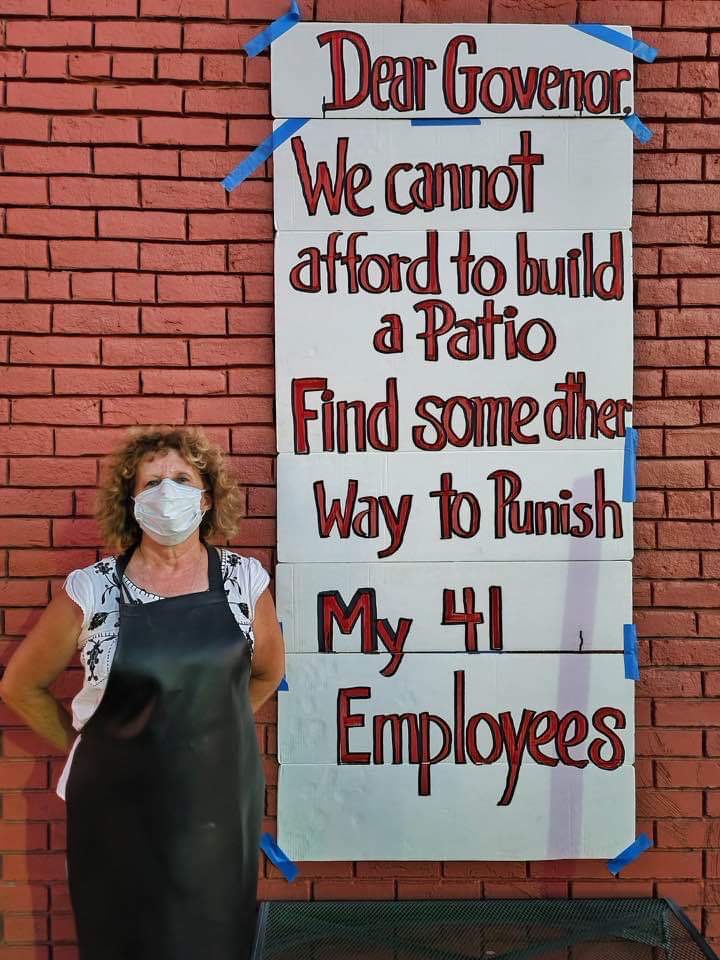

Stacy Boyne